Case Study.

General Motors® enhances safety and minimizes liability with innovative polymer fusion labeling solutions from Polyfuze®.

Since 2018, General Motors has used Polymer Fusion Labeling on over 6.5 million TPV wireless phone charging pads across more than 30 vehicle badges.

Case Study.

General Motors® enhances safety and minimizes liability with innovative polymer fusion labeling solutions from Polyfuze®.

Since 2018, General Motors has used Polymer Fusion Labeling on over 6.5 million TPV wireless phone charging pads across more than 30 vehicle badges.

2024 Case Study

How GM Improved Over 6.5 Million Vehicle Wireless EV Charging Pads with Fusion Labeling

Table of Contents

Executive Summary

GM Meets Safety Standards with Fusion Labeling

General Motors® (GM) required durable labeling for wireless EV charging pads in their vehicles, capable of withstanding exposure to sunscreens, insect repellents, and perspiration over a minimum lifespan of 15 years. Traditional labels failed these conditions. Polyfuze®’s polymer fusion labels, compatible with Santoprene® TPV, met GM’s demanding standards, leading to their adoption in 2018 for all new vehicles with TPV wireless EV charging pads. Notably, Polyfuze technology, under the technical name “Fused,” was added to GM’s approved materials listing for use on Polyolefin Thermoplastic materials for a “Life of Vehicle” use case, enabling Design Release Engineers to utilize it in their projects.

Background

Who Is General Motors?

General Motors® is one of the largest automotive manufacturers in the world, known for its commitment to safety, sustainability, and quality. GM’s four core brands include Chevrolet, GMC, Cadillac, and Buick. In the automotive industry, the use of plastics like polyethylene (PE), polypropylene (PP), and now thermoplastic vulcanizate (TPV) is prevalent, making up approximately 66% of the materials in vehicle assembly, selected for their superior durability and performance properties, ensuring adherence to the industry’s rigorous standards for vehicle reliability and longevity.

The Problem

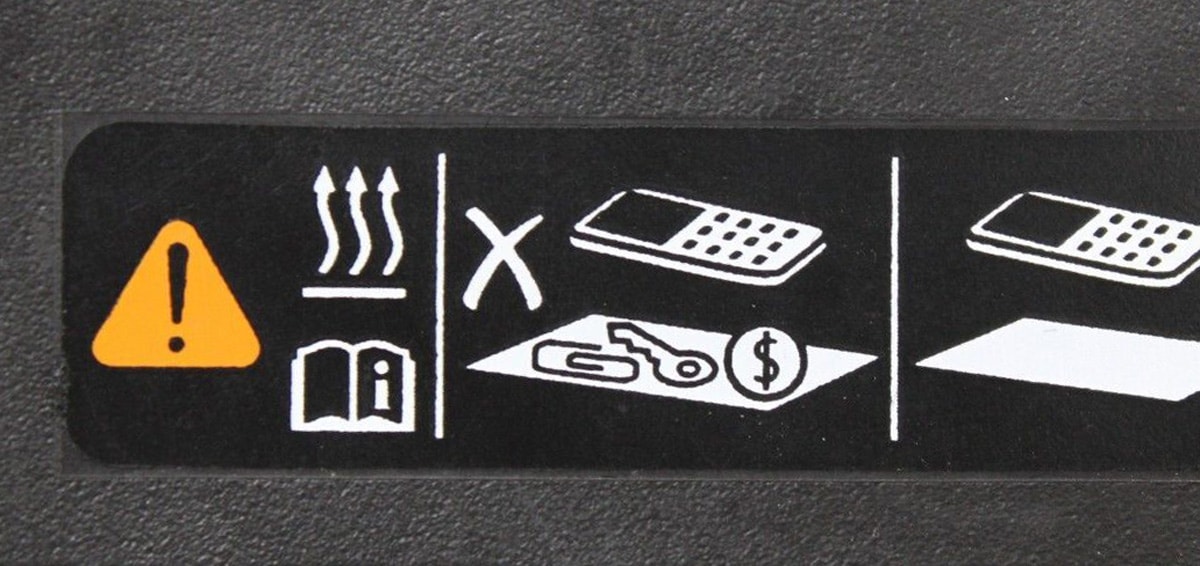

Challenges Faced In Labeling Wireless EV Charging Pads

After introducing wireless EV charging pads in new models, GM faced challenges in labeling these pads with safety warnings. Traditional heat transfer labels on Santoprene® TPV failed GM’s stringent tests for sunscreen, insect repellent, and perspiration resistance, leading to delamination and peeling. This prompted the need for a more resilient labeling solution that could withstand these exposures for at least 15 years, maintaining the integrity and safety warnings crucial for consumer use.

The Solution

Polymer Fusion Labeling

Polyfuze’s Polymer Fusion Labeling Technology offered a revolutionary approach. Unlike traditional methods, it fused labels to polyolefin thermoplastics at a molecular level, ensuring long-lasting safety information. These labels not only fused seamlessly with the pads but also met the 15-year lifespan requirement. Successfully passing GM’s GMW14445 test for resistance to sunscreen and insect repellent, as well as all GMW14573 performance tests, these labels demonstrated superior resilience.

By 2018, General Motors officially recognized Polyfuze technology’s value, incorporating it under the technical name “Fused” into their engineering standards and approved materials listing for Polyolefin Thermoplastic materials. This inclusion for a “Life of Vehicle” use case empowered Design Release Engineers to apply this innovative labeling solution across various projects.

Sure enough, we stamped the Polyfuze Label, then I took a knife to it and it was fused in there! That blew me away! You couldn’t do that with a heat transfer… I can say that our scrap rate, using Polyfuze versus heat transfers, is far less… Once you start using it, it sells itself.

– Rubbermaid Engineer

The Result

GM Implements Polymer Fusion Labels

Polymer fusion labeling from Polyfuze® enabled General Motors to permanently adhere to stringent safety standards, safeguarding customers and reducing liability. This technology not only met GM’s rigorous safety requirements but also presented a cost-effective solution compared to the previous heat transfer labels.

Since integrating Polyfuze’s technology in 2018, TPV Wireless Charging pads in over 6.5 million vehicles have been labeled for life. This achievement underscores Polyfuze’s pivotal role in fulfilling the specialized labeling needs within vehicle production for GM and sets the stage for future collaborations with other automotive giants like Ford and Honda.

The partnership between General Motors and Polyfuze exemplifies how innovative labeling technology can significantly enhance product functionality and compliance, as evidenced by the successful application of durable, polymer fusion labels to over 6.5 million TPV Wireless Charging pads in GM vehicles, setting a new standard in automotive labeling. This case study not only highlights the technical achievement but also underscores the strategic importance of incorporating advanced materials into GM’s engineering protocols to ensure product longevity and compliance.

The Problem: Traditional Methods

The Solution: Polymer Fusion Labeling

Written By:

Matthew Stevenson

Published On:

January 1, 2024

Share: